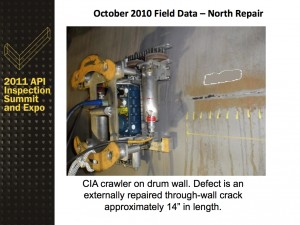

CIA made a presentation to the API (American Petroleum Institute) Inspection Summit on its progress with the Remote Robotic Inspection Service. The presentation provides a background on how and why CIA Inspection developed the system and includes results of scans conducted in a coke drum that was to undergo repairs.

The field tests allowed us to gain further understanding of real world indications and how they appear to the ACFM system. It is clear that we can identify cladding stretch marks (elephant skin), weld anomalies and repairs, and size small, medium and large cracks. Comparisons of ACFM inspection findings to the depths of cracks ground out and repaired by the site show that the ACFM results were very close to the site’s findings, with the average difference only 0.063 inches (63 thousandths of an inch) for the 7 areas scanned.

Below are four concepts by which all inspection techniques can be measured and the findings from the field trial:

- Repeatability – The same area, examined multiple times, should produce near identical results when examined by the same analyst. Of 3 areas where multiple readings were taken (1 x 4, 2 x 2 readings), the maximum difference was 0.098” and the average (using the maximum delta) was 0.059”

- Internal Consistency – When the same data is analyzed by different trained users the results should be similar. Of 11 matching readings, average difference was 0.036”, maximum was 0.084”

- External Consistency – When defects are analyzed by another technique, results should be close, with allowances for limitations of each technique in specific situations. Of the 7 comparable areas in the drum the average difference was 0.063”

- Reliability – No defects of a specific minimum size should be missed. For coke drums a starting point is defects longer than 0.75 inches and deeper than 0.08 inches, the approximate thickness of the stainless cladding.

Our analysis of these results is that CIA’s ACFM system

- Was successful in identifying and sizing defects.

- Overcame the challenges of real world cracks in coke drums in that they tend to close up in cold drums and so may present as a series of shorter cracks. Defects in live, hot drums should be easier to find

- Allows straight forward identification of actionable anomalies even if precise sizing is imperfect

Bottom line is that CIA is confident we can deploy our system remotely into a coke drum and detect defects that would cause concern — ACFM works in the coke drum environment!

To download the PowerPoint Presentation complete with 2 short .MOV clips ‘right click’ here and select “Download Linked File”. The file is a zipped directory containing the 3 files and the total download is 61.3 MB. Once unzipped open the PowerPoint file and view as a slide show; the movies are in Apple QuickTime format and will start when the image is clicked on.